- Shenzhen Chaosheng Electronic Technology Co., Ltd.

- Main products: HDImulti-layer PCB, Soft hard combination flexible FPC, HDI multi-layer PCB, Oversized Circuit Board (PCB), Multi layer ultra large size PCB, HDI flexible FPC, Multi layer ultra large size circuit board PCB, Roll to roll flexible FPC, Multi layer flexible FPC, Double layer roll to roll flexible FPC, PCBA, Multi layer thick copper circuit board PCB, PCB, Ultra long size thick copper PCB, Flexible FPC,Soft hard combination flexible FPC, HDI circuit board PCB, Multi layer aluminum based PCB, Thermoelectric separation multi-layer aluminum based PCB, Thermoelectric separation copper based PCB, Thick Gold Circuit Board PCB, High frequency mixed voltage multi-layer PCB, Ultra long size thick copper PCB, HDImulti-layer PCB, Soft hard combination flexible FPC, HDImulti-layer PCB, Soft hard combination flexible , Communication server circuit board PCB, Flexible FPC,Soft hard combination flexible FPC, HDI circuit board PCB, HDI high-frequency PCB, Multi layer aluminum based PCB, Thermoelectric separation multi-layer aluminum based PCB, Thermoelectric separation copper based PCB

Home > Company News > China Super Sheng Panasonic R-1785 high-frequency board uses Panasonic materials

Company News

Panasonic Develops Glass Composite Circuit Board Material that Improves Parts Mounting Reliability

Panasonic's new glass composite circuit board material improves the mounting reliability of electronic circuit board parts, thereby contributing to the long-term stable operation of automotive and industrial equipment.

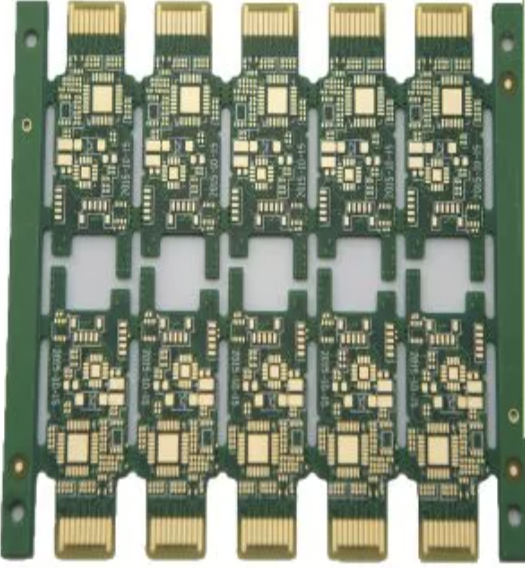

High reliability Glass composite circuit board materials R-1785

Glass composite circuit board materials R-1786, R-1781

Thick copper glass composite circuit board materials R-1786

Osaka, Japan - Panasonic Corporation announced today that it has developed a glass composite circuit board material (product number: R-1785) suited for automotive and industrial equipment. Mass production is scheduled to start in June 2018.

With the ever-increasing use of electronics in vehicles and recent trend toward high functionality of various industrial equipment, electronic circuit boards now require excellent parts mountability and compatibility with high currents. Panasonic has developed a glass composite circuit board material (CEM-3 grade) that achieves the industry's lowest*1 coefficient of thermal expansion (CTE) [1] by using its unique manufacturing method and resin design technology, thereby contributing to the improvement of parts mounting reliability and compatibility with high currents for electronic circuit boards.

Panasonic's new glass composite circuit board material has the following features:

The industry's lowest*1 coefficient of thermal expansion that improves the parts mounting reliability of electronic circuit boards

• Coefficient of thermal expansion 15 – 17 ppm/°C (α1) (Board thickness: 0.8 mm)

• Panasonic's conventional product*2: 20 – 23 ppm/°C (α1) (Board thickness: 0.8mm)

Excellent tracking resistance [2] compatible with the miniaturization of high-current circuit boards

• Comparative tracking index (CTI) ≥ 600 V

• Panasonic's conventional product*3: 250 V > CTI ≥ 175 V

Highly accurate board thickness that contributes to the stable operation of electronic circuit boards

• Board thickness accuracy: ±0.05 mm (Board thickness: 1.6 mm)

• Panasonic's conventional product*3: ±0.10 mm (Board thickness: 1.6 mm)

(Twice the accuracy)

Notes:

*1: As a glass composite circuit board material (CEM-3 grade) as of June 4, 2018 (Panasonic data)

*2: Panasonic's conventional product (General glass composite circuit board material, Panasonic product number: R-1786)

*3: Panasonic's conventional product (General glass epoxy circuit board material, Panasonic product number: R-1705)