- Shenzhen Chaosheng Electronic Technology Co., Ltd.

-

Shenzhen, Guangdong, China

- Main products: HDImulti-layer PCB, Soft hard combination flexible FPC, HDI multi-layer PCB, Oversized Circuit Board (PCB), Multi layer ultra large size PCB, HDI flexible FPC, Multi layer ultra large size circuit board PCB, Roll to roll flexible FPC, Multi layer flexible FPC, Double layer roll to roll flexible FPC, PCBA, Multi layer thick copper circuit board PCB, PCB, Ultra long size thick copper PCB, Flexible FPC,Soft hard combination flexible FPC, HDI circuit board PCB, Multi layer aluminum based PCB, Thermoelectric separation multi-layer aluminum based PCB, Thermoelectric separation copper based PCB, Thick Gold Circuit Board PCB, High frequency mixed voltage multi-layer PCB, Ultra long size thick copper PCB, HDImulti-layer PCB, Soft hard combination flexible FPC, HDImulti-layer PCB, Soft hard combination flexible , Communication server circuit board PCB, Flexible FPC,Soft hard combination flexible FPC, HDI circuit board PCB, HDI high-frequency PCB, Multi layer aluminum based PCB, Thermoelectric separation multi-layer aluminum based PCB, Thermoelectric separation copper based PCB

-

Mank.Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Mank.Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

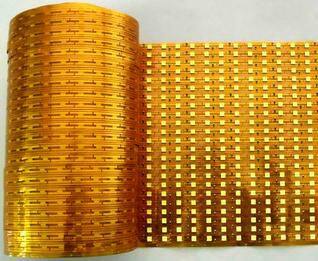

Introduction to Multi layer Flexible FPC

2025-07-26 17:50:08

Introduction to Multi layer Flexible FPC

Multi layer ultra long flexible FPC is an advanced flexible printed circuit board. The following will provide a detailed introduction from its structural characteristics, production process, application fields, and development trends:

structure and characteristics

Multilayer structure: It is composed of multiple conductive layers and insulating layers alternately stacked, and electrical connections between layers are achieved through plated through holes (PTH), which can realize complex circuit functions and improve circuit integration.

Ultra long size: Breaking through the traditional FPC size limitations, the length can reach several meters or even longer, meeting the needs of some special application scenarios for long-distance signal transmission and wiring, such as battery management systems for electric vehicles, large display devices, etc.

Highly flexible: Using flexible substrates such as polyimide or polyester, it has excellent flexibility and bendability, and can be bent, folded, and twisted arbitrarily in narrow spaces, adapting to various complex shapes and spatial layouts.

Thinning: The thickness is usually thinner and the weight is lighter, which helps to achieve the thinning and miniaturization of electronic products, while reducing the impact on the overall weight and volume of the device.

High performance: It has good electrical performance, such as low resistance, low capacitance, low inductance, etc., which can ensure the integrity and stability of high-speed signal transmission, reduce signal attenuation and crosstalk, and also has good heat dissipation performance and anti-interference ability.

Production process

Lithography technology: Using photolithography technology to transfer circuit patterns onto flexible substrates, by controlling lithography accuracy, achieving micrometer or even smaller line widths and spacing, ensuring high-precision and high-density wiring of circuits.

Etching process: Chemical etching or laser etching methods are used to remove unwanted copper foil or other conductive materials, forming precise circuit patterns. For multi-layer ultra long flexible FPCs, the etching process needs to be strictly controlled to ensure consistency and accuracy of each layer of the circuit.

Laminated process: Multiple layers of conductive and insulating layers are laminated together through a laminating process. During the lamination process, precise control of temperature, pressure, and time parameters is required to ensure good bonding between the layers and avoid problems such as interlayer misalignment and bubbles.

Drilling and through-hole plating process: Laser drilling or mechanical drilling technology is used to form through holes on multi-layer FPC, and then metal is deposited on the hole walls through through-hole plating process to achieve electrical connections between layers. The accuracy of drilling and the quality of plated through holes directly affect the electrical performance and reliability of FPC.

Surface treatment process: Treat the surface of FPC, such as gold plating, tin plating, coating with solder resist, etc., to improve the solderability, oxidation resistance, and wear resistance of the circuit, and protect the circuit from external environmental influences.

application area

Consumer electronics: widely used in smartphones, tablets, laptops, wearable devices, etc., such as connecting display screens and motherboards, cameras and motherboards, etc., can achieve compact layout and lightweight design inside devices.

Automotive electronics: Used for battery management systems, in car infotainment systems, advanced driver assistance systems (ADAS), etc. in automobiles, it can meet the reliable working requirements of automobiles in harsh environments such as vibration and high temperature, and also contribute to the lightweighting and wiring optimization of automobiles.

Medical equipment: such as portable medical instruments, implantable medical devices, etc., multi-layer ultra long flexible FPC can provide high reliability circuit connections and adapt to human bending and movement, meeting the requirements of medical equipment for miniaturization, flexibility, and biocompatibility.

Aerospace: In high-end equipment such as satellites and spacecraft, it can meet strict requirements for high reliability, lightweight, and space saving, and is used to connect various electronic devices and sensors to ensure stable operation in space environments.

Industrial automation: used in industrial robots, automated production lines, and other equipment to achieve complex circuit connections and signal transmission, while adapting to the vibration and bending of the equipment during operation.

development trend

Higher integration: With the continuous development of electronic products towards miniaturization and multifunctionality, the integration requirements for multi-layer ultra long flexible FPCs are becoming increasingly high. In the future, higher density circuit wiring and integration of more functions will be achieved.

High speed and high frequency: In order to meet the needs of applications such as 5G communication and high-speed data transmission, multi-layer ultra long flexible FPCs will continuously improve signal transmission speed and frequency, reduce signal loss and crosstalk, and develop new materials with lower dielectric constants and lower loss factors, which will become key.

Intelligent Manufacturing: Utilizing technologies such as artificial intelligence and machine learning to achieve automation and intelligent control of the production process of multi-layer ultra long flexible FPC, improving production efficiency, product quality, and consistency, and reducing production costs.

Environmental Protection: Developing more environmentally friendly production processes and materials to reduce environmental pollution during the production process, while improving the recyclability and degradability of FPC, in line with the requirements of sustainable development.

Tags: ultra large size transparent circuit board PCB, ultra large size multi-layer circuit board PCB, Multilayer thermoelectric separation copper based PCB